Once Through Cooling Water 일회 냉각 방식이란 INSIDE INSIGHTS

Water-Cooled Condensers #3: Coaxial tube-in-tube. Overview: Coaxial tube-in-tube is the third type of condenser in a water-cooled chiller. It earns its name because the tubes are coiled around the same axis. Excellent anti-fouling characteristics make these high-performance and compact heat exchangers stand out from other condenser types.

Shell and Tube type water cooled condenser in hindi YouTube

Water-cooled condensers are perfect for applications where air-cooled condensers would not be practical and/or areas where water is readily available. These units provide an economical, compact alternative to traditional air-cooled condensing units. Quick Links Literature Support Catalog Product Styles 0.75 - 22 HP

Solved A watercooled condenser in a large refrigeration

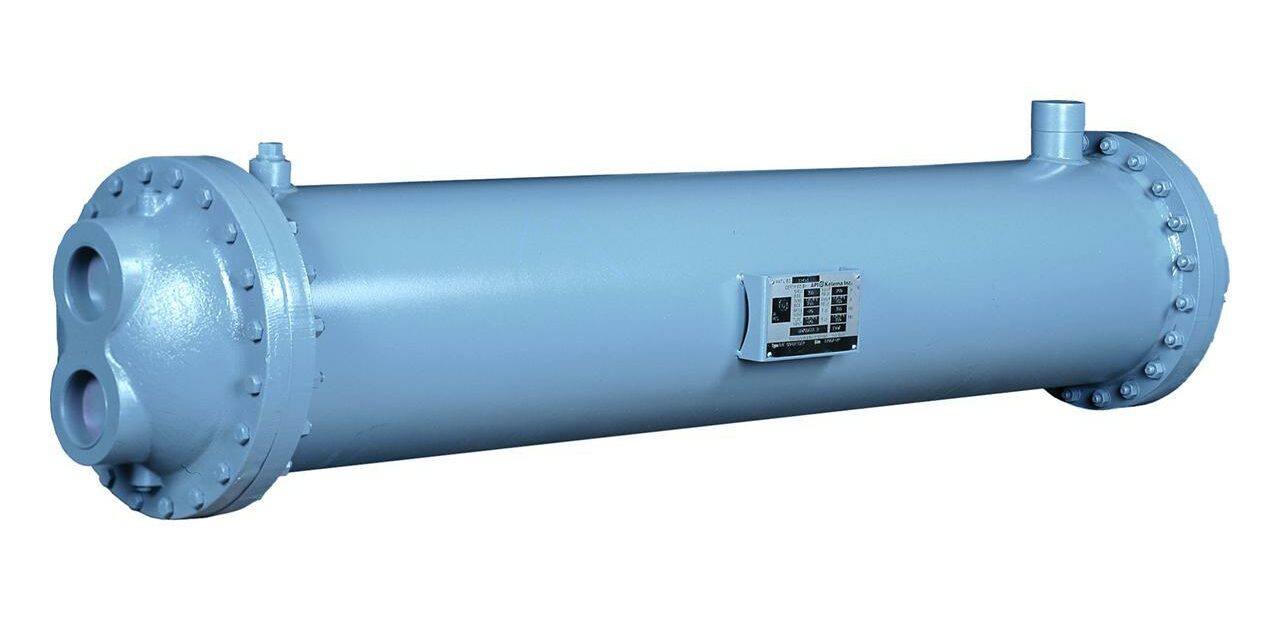

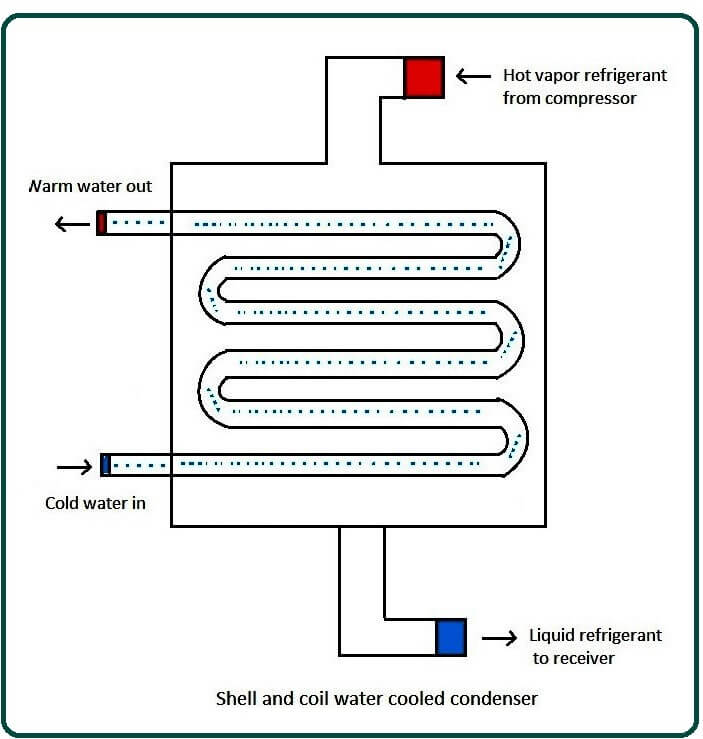

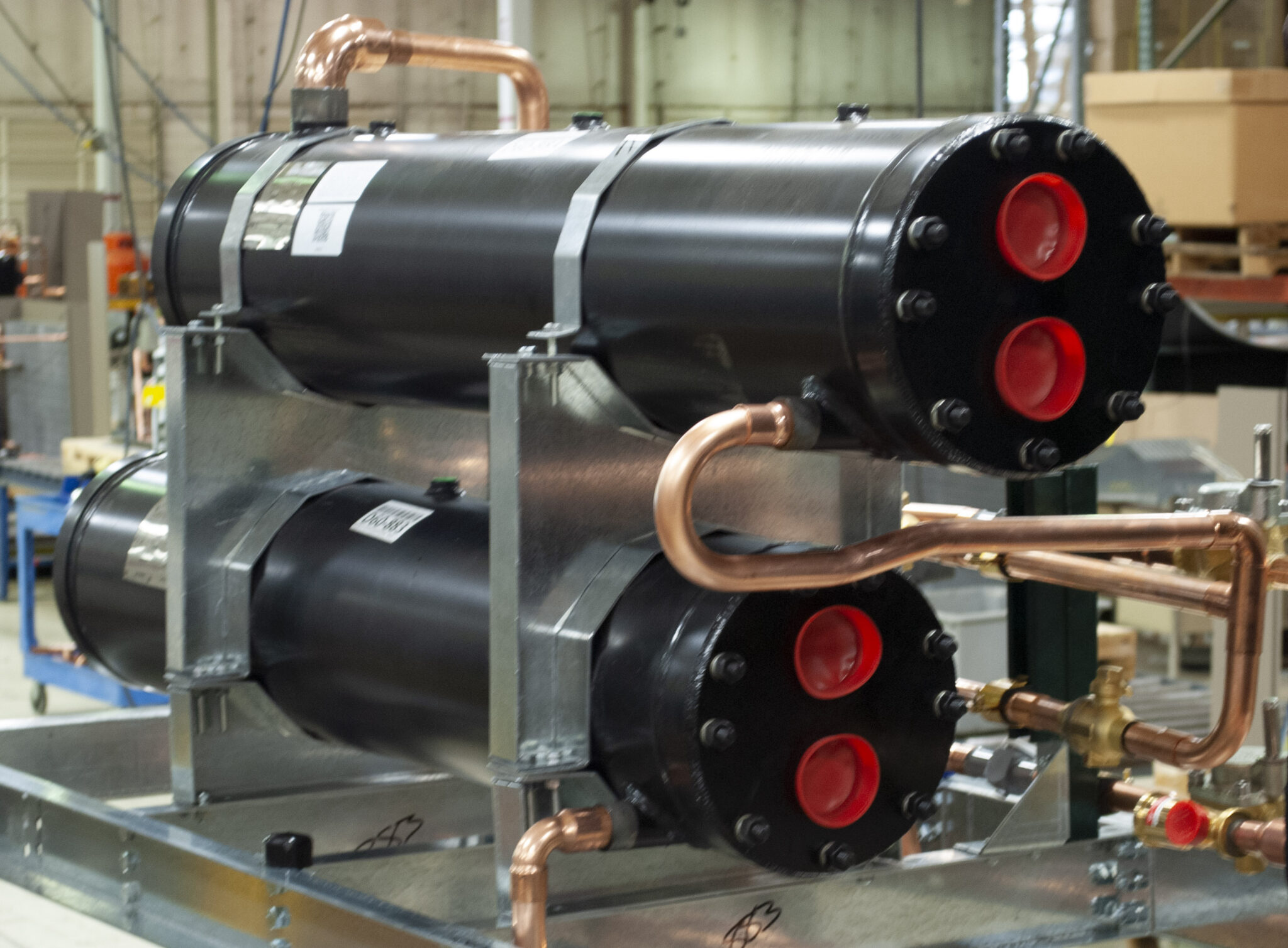

Copeland® water-cooled condensing units are available in a wide variety of sizes, and three different styles of condensers are currently in production: shell and tube, shell and coil, and tube within a tube. Table 1 lists the approximate water flow requirement on Copeland® condensing units for various evaporating and condensing temperatures.

Working Principle of Condenser and its Types Food Tech Notes

• 12-20°F ΔT chilled water • 12-18°F ΔT condenser water CoolTools™ Chilled Water Plant Design and Specification Guide, 200011 • 15-18°F ΔT chilled water Kelly and Chan, Optimizing Chilled Water Plants, HPAC Engineering, 199912 • 18°F ΔT chilled water • 14°F ΔT condenser water 1 ANSI/ASHRAE/IES, 2016.

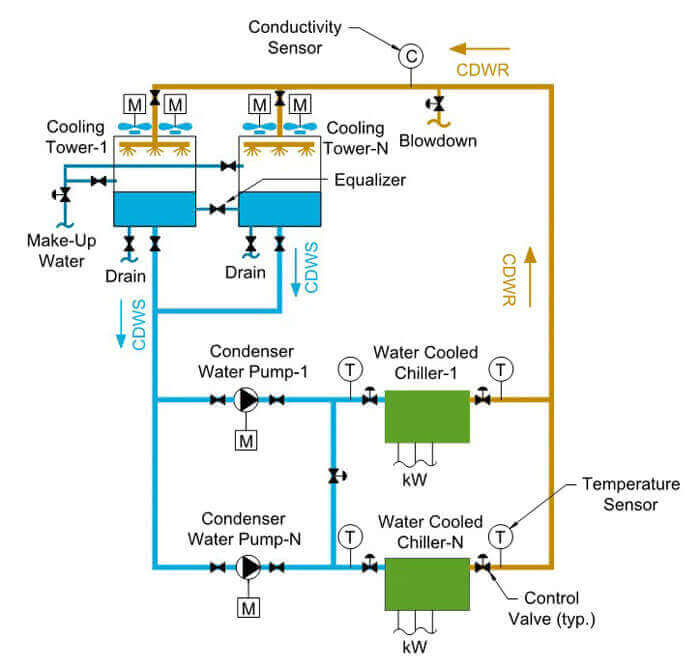

Condenser Water Pump Design Guide, How to Size and Select a Condenser

Water-cooled condenser To cool a building or process, the transferred heat must ultimately be rejected outdoors or to another system (heat recovery). The total amount of heat rejected includes the sum of the evaporator load, the compressor work, and the motor ineffi ciency. In a hermetic chiller, where the motor and compressor

Seawater Cooled Condensers FreezeTec Brisbane & Gold Coast

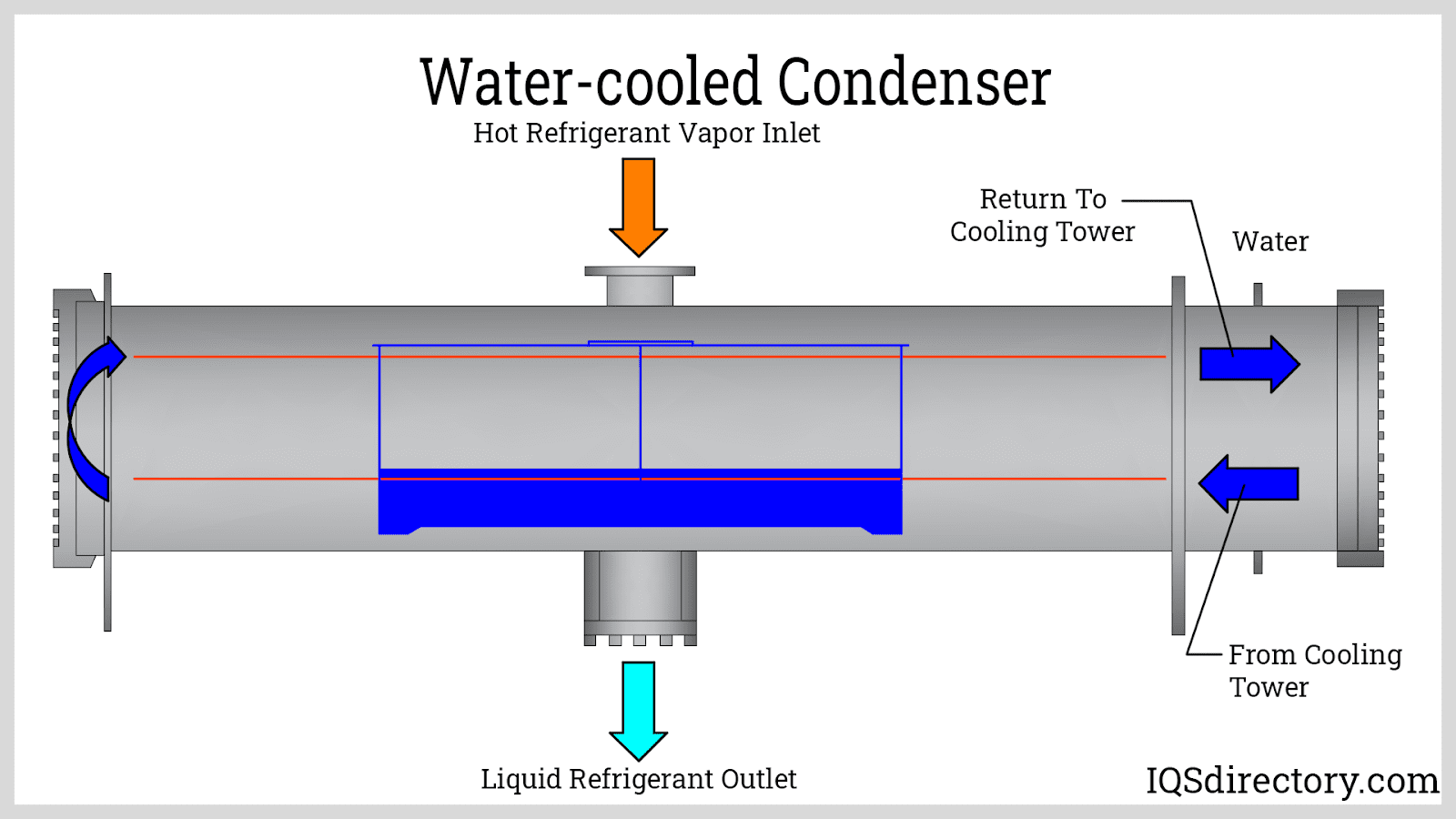

A water-cooled condenser diagram is a visual representation of the components and processes involved in cooling and condensing vaporized refrigerant using water as the cooling medium. The diagram typically includes labeled parts such as the condenser coil, water inlet and outlet, compressor, and expansion valve..

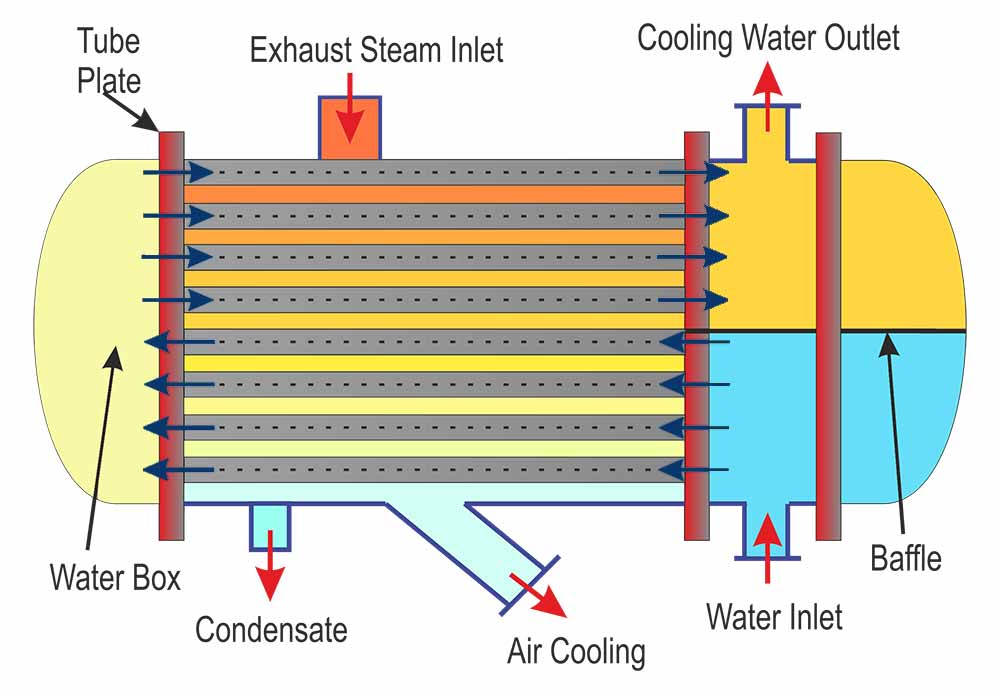

Surface Condenser Types Of Surface Condenser

Condenser fouling is one of the common faults in water-cooled chillers that degrade its energy efficiency. Studies were conducted to develop fault detection and diagnostics (FDD) algorithms to.

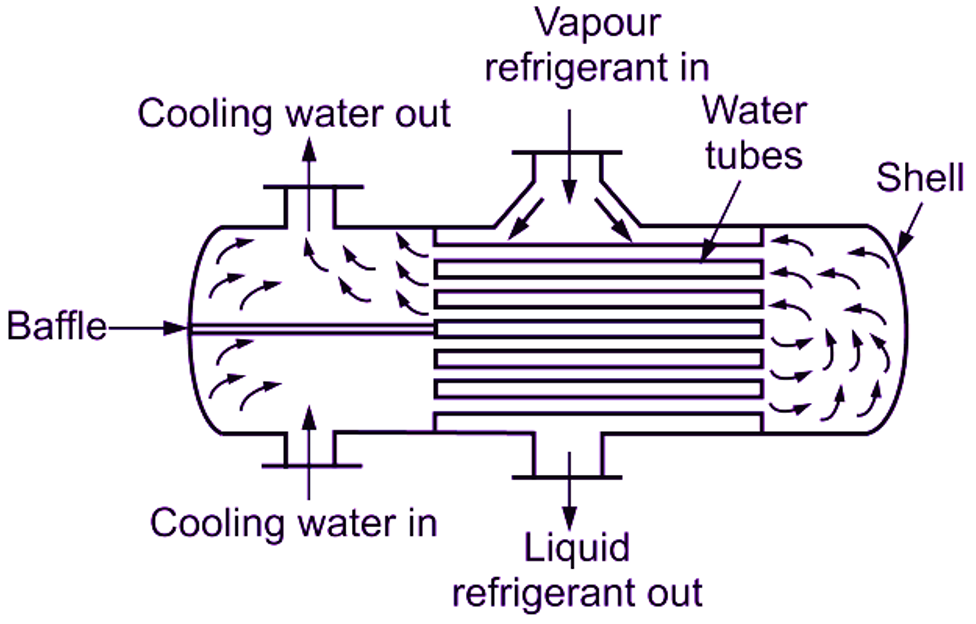

What is Shell and Tube Condenser? Working, Construction & Diagram

Sequence of Operation. When the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. When operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the.

Water cooled condenser types A goto guide to choosing the right one

For R134a and R290/R600a, the TEWI of the system with water-cooled brazed plate heat exchanger is lower than that of the system with air-cooled condenser by 26.8% and 21%, respectively.

Schematic of the condensing water loop of a watercooled chiller

Learning Objectives Obtain an overview of basic condenser water design considerations. Learn the opportunities to improve water quality and conserve water through system design. Understand the relationship between various strategies and components and the importance of a fully integrated system approach.

Electrical Rules and Calculations for AirConditioning Systems Part

Qi Fu To solve the problems of single heat source heat pump systems in severe cold regions, a dual-source hybrid heat pump unit (DSHHPU) is proposed. The mathematical models of the DSHHPU when.

Water Cooled Condenser Diagram Diagram Quizlet

What Is a Water-Cooled Condenser? It is a technical heat exchanger used to remove heat from the refrigerant vapor and transfer it to the water running inside the tube. Water-cooling systems have seen considerable use over the years, although they are also increasing in small businesses & some residential applications.

How Does a Condenser Work? Different Types of Condensers

Water-cooled condensers involve a heat rejection loop where condenser heat is dissipated to the environment via water. The most common type of water-cooled condensers in geothermal power plants are direct-contact and surface types.

Surface Condenser in Thermal Power Plant Watco Group

The evaporative condenser is essentially a combination of a water-cooled condenser and an air-cooled condenser, utilizing the principle of heat rejection by the evaporation of water into an air stream traveling across the condensing coil.

The Three Types of WaterCooled Condensers Drake Refrigeration, Inc.

A typical water-cooled chilled water system consists of 4 major components as below: Chiller Cooling Tower Chilled Water Pump Condenser Water Pump Each component has a lot more to talk about but, in this post, I'll give you an overview of them and explain through the chilled water system as a whole.

Water Chiller What Is It? How Does It Work? Types, Uses

detailed information on water cooled condensers https://www.sciencedirect.com/topics/engineering/water-cooled-condenserThe News water cooled condenser troubl.